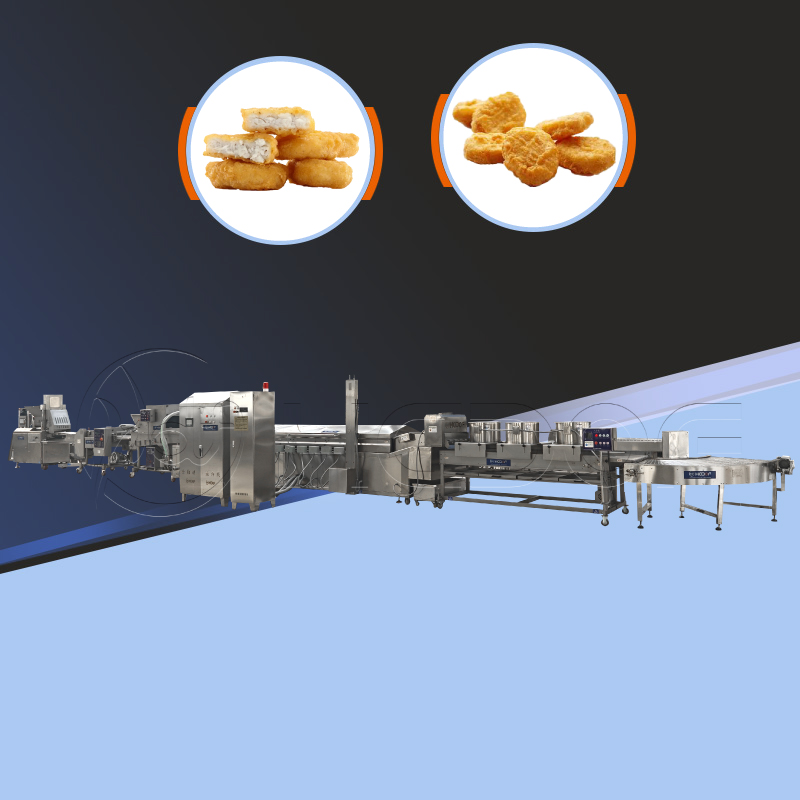

The chicken nugget production line is a fully automated processing system designed to efficiently complete the entire workflow from raw meat preparation to finished chicken nuggets. The line is composed of a meat grinder, vacuum mixer, nugget forming machine, battering machine, breading machine, continuous fryer, de-oiling machine, and cooling or freezing system.

The production process begins with grinding and mixing the raw chicken meat with seasonings to achieve a consistent texture. The forming machine then shapes the mixture into uniform nuggets, which pass through battering and breading machines to create an even coating. The coated nuggets enter the continuous fryer for precise and stable frying, followed by a de-oiling unit that removes excess oil. Finally, the nuggets are cooled or quick-frozen to maintain quality, texture, and shelf life.

All equipment is made of food-grade SUS304 stainless steel, ensuring durability, hygiene, and corrosion resistance. With adjustable speed, stable performance, high efficiency, and easy cleaning, the chicken nugget production line is suitable for food factories of various scales. It ensures consistent product quality, reduces labor costs, and supports continuous, high-capacity production.

Material:

Our food machines are made of food-grade SUS304 stainless steel, ensuring long-term use without rust or corrosion.

Professionalism:

Installation, commissioning, and technical training are provided by professional technicians. The equipment comes with a one-year warranty and lifetime technical support.

Energy Consumption:

Designed with an energy-saving heating system and precise temperature control to reduce power and fuel consumption while maintaining high frying efficiency.

Service Guarantee:

We provide professional installation, on-site training, a one-year warranty, and lifetime technical support to ensure long-term stable operation.

The chicken nugget production line is widely used in the following areas:

- Frozen Food Processing Plants: For producing frozen chicken nuggets, popcorn chicken, chicken patties, and other coated foods.

- Central Kitchens & Chain Restaurant Supply Centers: To supply standardized and mass-produced chicken nugget products for fast-food chains.

- Ready-to-Cook / Ready-to-Eat Food Factories: Suitable for producing pre-fried, ready-to-cook, and ready-to-eat chicken snacks.

- Meat Deep-Processing Enterprises: Transform raw chicken into higher-value processed meat products.

- Cold Chain Food Manufacturers: For large-scale production of frozen nuggets, chicken strips, and similar items.

- Catering & Institutional Food Suppliers: Serving hotels, restaurants, schools, and large catering services.

- Food Trading Companies / OEM Factories: For contract manufacturing for supermarkets, brands, and export markets.

- Extended Application for Battered & Breaded Products.

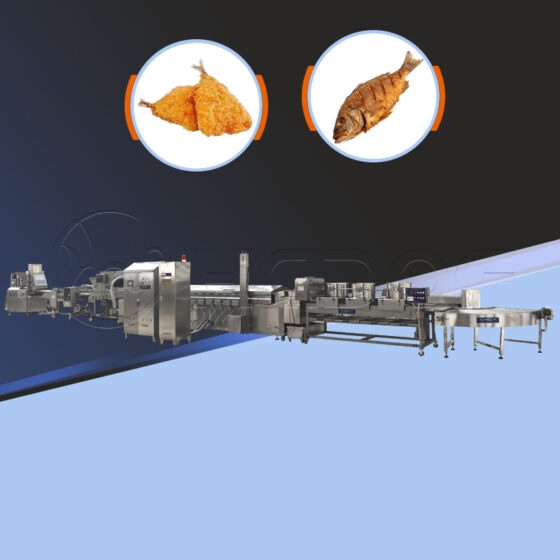

- The same line can also process: Fish nuggets, shrimp nuggets, Vegetable nuggets (potato, pumpkin, etc.), Chicken patties, strips, meatballs, Beef or pork formed products。

Raw Meat → Mixing → Forming → Battering → Breading → Frying → De-oiling → Cooling → Freezing → Packing

Potato frying machines and production line

Potato frying machines and production line

×

×

WeChat

Scan the QR Code with wechat