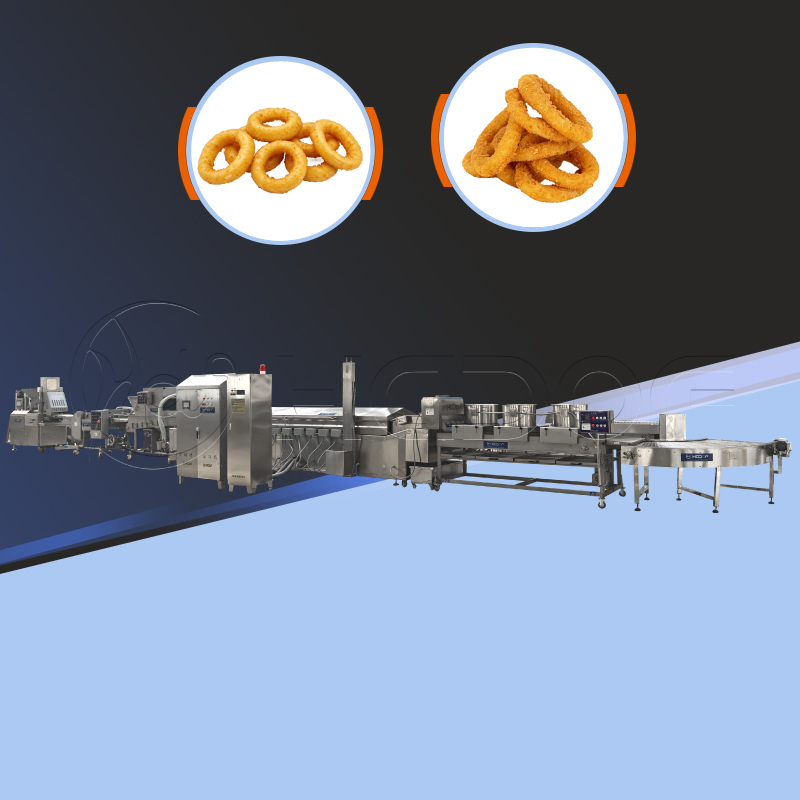

The onion ring frying production line is designed for continuous and automatic processing of breaded onion rings. The line integrates peeling, slicing, ring separation, battering, breading, frying, de-oiling, cooling, and optional freezing processes to ensure stable quality and high efficiency.

Made of food-grade SUS304 stainless steel, the production line features hygienic design, precise temperature control, and adjustable conveyor speed. It ensures uniform coating, consistent frying results, and crispy texture, making it suitable for industrial-scale onion ring production.

Uniform coating and stable frying quality

Energy-saving heating system with precise temperature control

Continuous production with high efficiency

Easy cleaning and maintenance

One line suitable for multiple breaded vegetable products

The onion ring frying production line is widely used in:

Frozen food processing plants

Fast food and snack food factories

Central kitchens and chain restaurant suppliers

Ready-to-cook and ready-to-eat food manufacturers

Export-oriented food processing enterprises

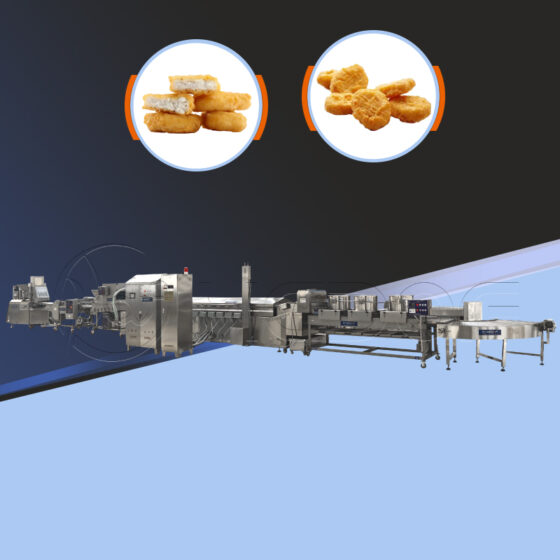

The line is also suitable for producing other battered and breaded vegetable products such as zucchini rings, mushroom slices, and vegetable fritters.

Fresh Onions → Peeling → Slicing → Ring Separating → Washing → Battering → Breading → Continuous Frying → De-oiling → Cooling → Freezing (Optional) → Packaging

Potato frying machines and production line

Potato frying machines and production line

×

×

WeChat

Scan the QR Code with wechat